Let's get started. Please refer to the attached manual and assemble the main unit.

* Products might be improved or minor changes being made without prior notice.

Please understand in case there are some minor differences from models you use.

Preparation

Please put more than 10kg (22lb) of media into the tank.

Three quarters of the tank as a guide, up to about 20kg (44lb) of media can be put in.

When tightening the media regulator at the top of the tank after putting the media in, please ensure to insert the shaft vertically into the center of the tank and carefully tighten the screw.

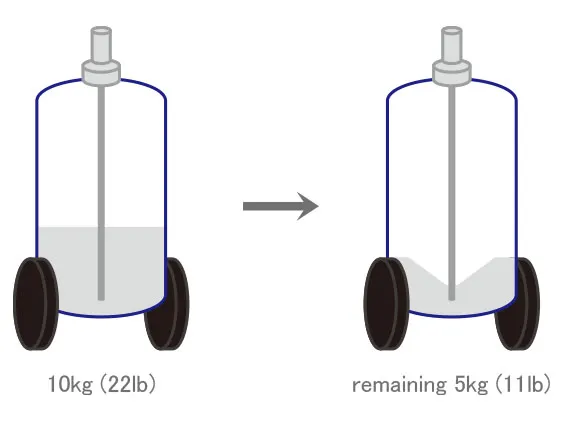

If it is not injected stably, one of the causes can be the media shortage in the tank.

In terms of the structure of the product, a whole amount of media you put in cannot be used up cleanly.

Supply of the shaft in the tank to the media inlet gets worse if the media amount becomes remaining lower.

It is not surprise that you may waste the media for the first time. Becoming accustomed to the work or not would affect results as it is a kind of machine and tool.

When the media gets remaining lower in the tank during operation, please swing/ shake/ jounce gently the tank in order to reshape the media and collect to the inlet.

Please check the demo video "How to use 2".

Connect the supplied water hose to the faucet and open it.

We cannot articulate exactly how much faucet should be opened because water pressure and discharge amount are different depending on location and environment. However, we assume that it will be fine to open the faucet fully since it is still adjustable with the valve at the hand nozzle during operation.

Water does not get mixed into the tank. The media will be dissolved due to water solubility. We prepared a setting to switch dry and wet at hand.

Connect the air hose from the compressor and fill the tank with air. It is usually set around 0.6 MPa, but please adjust according to the material you will apply to.

The ability of the compressor is equivalent to power of work. We recommend a compressor with at least 3 horsepower or above. Even with 3 horsepower, sometimes it is necessary to operate with interval breaks/ pause depending on the discharge amount.

A simple type of water separator is attached to the supplied air regulator.

When baking soda contains moisture, it will get hard and worse flowability. If the media gets clumps in the tank, it will cause hindering stable injection.

It is necessary to add an air dryer or a water separator if the media is mixed with much moisture. Moisture is the worst for all air tools.

Ideally, there should be no clumps, and it should be a condition which collapses without remaining a hole when poke heap of the media with a finger.

Please sift baking soda accordingly before putting the media into the tank.

Please continue to check the demo video in "How to use 2" for the state of stable injection in various media.